Why Are We the Best

Customized Solutions facilitating repairs inexpensively and avoiding operations shut down

Nationwide Service for Large-scale Projects

Commitment to Quality and Customer Satisfaction

Your Trusted Surfacing Partner

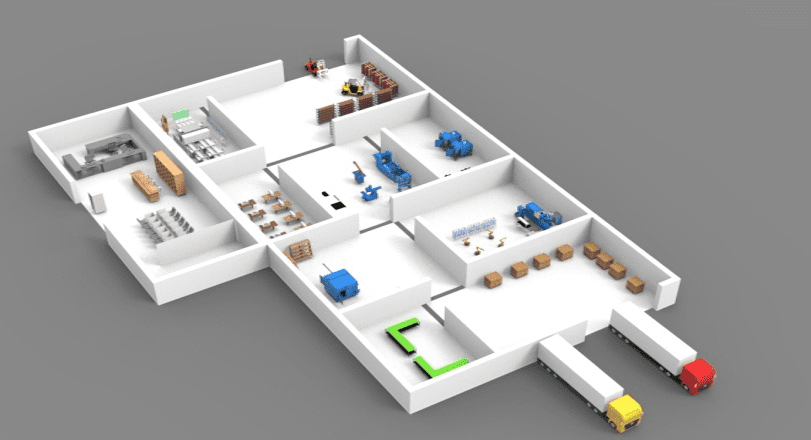

At Pro Surfacing, we provide a comprehensive range of surface systems designed to meet the unique needs of industrial food and beverage environments. Whether you're managing a high-traffic production facility exposed to harsh chemicals and heavy wear or a food prep area requiring sanitary, slip-resistant surfaces, our expert team is ready to recommend the ideal flooring solution tailored to your specific demands.

We specialize in assessing surface challenges and applying our expertise to offer custom solutions across various settings. From durable epoxy coatings to advanced plastic liners, we have the flexibility and knowledge to address a wide range of surface issues. Reach out to us today for a free consultation, and let us help you find the perfect resurfacing solution for your facility.

Did You Know Your Building Needs Us?

Admin Office/Space

These areas are not often thought of as potential plant “problem areas.” However, thousands of dollars are spent trying to keep safe, clean and pest free! We provide surface repair solutions here as well- such as sealants, coatings, polish floors, tiles, and niche’/ crack repair.

- 1 of 7

Chemical Room

- 2 of 7

Process Room

These areas make the product! Consequently, most of the harsh activity such as high temps, the introduction of chemicals and in some cases heavy mechanical activity- these areas are required to undergo the most ridged audit scrutiny (trying to locate and correct) items such as pesky microorganism activity as well as safety issues. Repairs inherently pop up on floors, walls and ceiling areas and we can help! Often times without having to shut down production!

- 3 of 7

Mechanical Room

These areas are frequently visited by mechanics trying to perform repairs to machines carrying oils, hot water, glycol and such. Subsequently, high traffic and spills cause surface damage. These areas need repair as well, due to safety as well as their proximity to process areas requiring High Hygiene.

- 4 of 7

Packaging

At this stage in the process, the product is finished but needs to be package! You can image the high level of cleanliness having to be maintained as well as the fast moving pieces and parts that cause substrate concerns. We go ya!

- 5 of 7

Office

- 6 of 7

Warehouse

Believe it or not, these areas require nearly the same level of quality scrutiny as the rest of the plant! The services we are often asked to provide here are floor grinding/ leveling, densifying and polishing, crack repair and injections and more!

- 7 of 7

Discover Our Services

Our team is ready to provide you with the best solutions tailored to your specific requirements. Explore our services to get more information on how we can meet your needs.